The African country aims to process its own raw materials rather than simply exporting them. To succeed, the country needs roads, electricity and skilled workers.

Zambia’s Minister of Mines enters the already packed conference hall. He has made it to Kinshasa, the capital of the neighboring Democratic Republic of Congo (DRC), in time for the panel discussion. It is not too late for his message either.

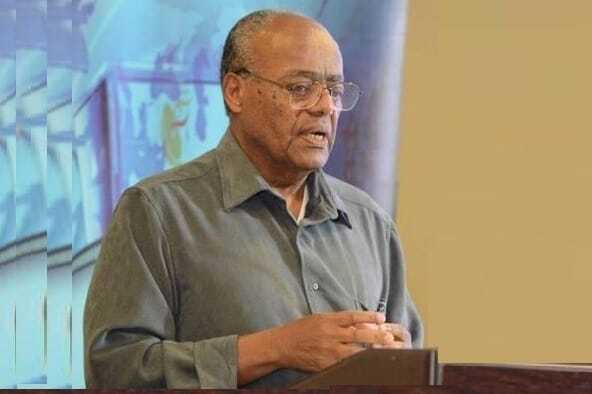

“We must stop exporting soil,” Paul Chanda Kabuswe tells the DRC-Africa Battery Metals Forum, a specialist conference on battery metals that aims to pave the way for a new industry in Congo.

“We must move up the value chain until the end so that now there will be benefits to the people that live where those minerals are.”

A new “scramble for Africa” is unfolding he says. The phrase hearkens back to the colonial period when European nations divided the African continent among themselves. Today, various companies and countries are signing treaties and partnerships with the continent, Kabuswe says. “And it is high time Africans started negotiating properly.”

From cobalt miner to battery producer

Today, Congo accounts for about two-thirds of global cobalt production. The metal is exported largely unprocessed and used primarily in batteries. Zambia also produces cobalt, which is important for the energy transition.

In November 2021, the heads of state of the two countries signaled their intention to process the raw materials locally. As a first step, they want to set up a special economic zone where the raw material is turned into preliminary products for the battery supply chain.

Vuko Ndondo Kakule, the deputy executive director of the Congolese Battery Council has even bigger plans.

“The DRC has set a goal to become one of the world’s largest battery producers around 2030 or 2040,” he says. At the conference, there is also talk of Congo as a future producer of e-cars.

Stakeholders from the industrialized countries are closely following as Congo tries to challenge the business model of exporting raw materials. On the podium of the Battery Metals Forum sits the ambassador of the United States, which has already issued a declaration of intent to support the special economic zone. A representative of the European Union, as well as Canadian and Chinese business leaders, are also talking part.

Raw materials from the region

Extracting raw materials is one thing, but refining them is much more difficult. Marie-Chantal Kaninda, the country manager of Glencore, a Swiss commodities giant, can tell you about this. The company mines cobalt in southern Congo. Metals could also be produced from it, she says.

“But at this stage, demand also has to be taken into account. If the products don’t find buyers, then the country doesn’t benefit either.” It pays currently to produce cobalt hydroxde, a powder that’s easy to transport, Kaninda added.

In addition to cobalt, lithium, nickel and manganese are also required for the production of basic batteries. And the primary product that Congo has in mind already contains all of these raw materials. Resources are available in the country, but they are not currently being mined.

This means that other countries would have to supply the planned special economic zone for the time being. The BloombergNEF research organization lists African countries such as Gabon, Madagascar and Zimbabwe in this regard.

According to a publication by the institute, building a plant in Congo to produce the precursor for a battery could cost only a third of an equivalent plant in China or the US. Compared to Poland, the cost is just under two-thirds. A pre-feasibility study for the project has been commissioned.

An ecosystem is needed

Jean Pierre Okenda sees many open questions. A feasibility study and raw materials in the country alone are not enough, he says.

“An ecosystem has to be built,” says the Conglese lawyer and country director of Resource Matters, an international NGO in the extractive industries sector.

There’s a lack of specialized workers, the necessary infrastructure for the transport of the raw materials — especially the electricity for large production plants, he says.

Local processing is already mandatory for many ores, but is not being carried out.

“It needs a really strong political will and high-level organizational skills,” says Okenda, who advocates for local value creation and realistic implementation.

“That’s why I also believe it should be a regional project and not left to the Congo alone.”

Chinese engagement

Against this backdrop, many companies want to wait and see what the Congolese government and its partners actually deliver. Specialized mining companies will hardly be able to get involved in further processing anyway. The most promising candidates therefore come from China, which already dominates the battery supply chain.

Zhou Jun is Vice President of CMOC, a group headquartered in Luoyang, China. They operate mines in Congo and support the government’s plans explicitly.

“This is a significant and promising development in which we will play an important role,” he says.

For one thing, local processing of raw materials helps us to reduce logistics costs,” he says, adding that the company’s goal is to promote industrial development in the Congo.

This article was translated from German.